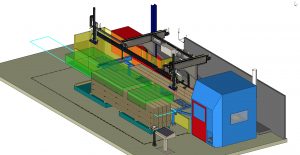

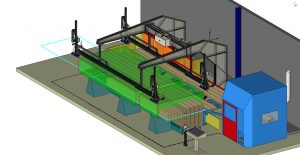

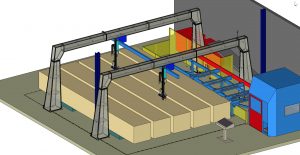

Vacuum lifting installation for delivering plank material

In particular for reducing the intensity of labour that is required for lifting and placing heavy beam and plank material on feed-in tables for wood processing machines, SenterTechnum offers a very economical and flexible ‘Vacuum lifting unit‘. The installation eliminates this critical link in your production process by reducing the risk of failure caused by overstretched employees.

Depending on layout and setup, this installation is capable of lifting beam and plank material of 2 to 12 meters in length and 60 to 500mm in width with a weight of 75 kg per lifting point. Through integrated laser technology, it will detect elements from multiple sets of stock material and will place this on a fixed position of the input table. This installation can process multiple elements per cycle, can stack material as well as detect curvature and align it at the input position. In ‘fast mode’ a cycle time of an average of 6 seconds per element is obtained from the nearest package. The most favorable lifting point position over the material length is set automatically. Inbetween slats in the supply package are automatically detected and removed.

The basic installation is supported by C-frames that extend from the rear right to the front over the infeed table of the wood-processing machine. This keeps the front of your machine free from obstructions for positioning stock material. Of course the integration of portal frames or roof truss suspension systems is also possible.

[Publicatie download: ‘Timmerfabrikant’ | november 2019]

Manufacturing facility for patented indoor wall system

Manufacturing facility for patented indoor wall system

Some time ago, Hopman Vastgoedonderhoud B.V. – NL launched its new and patented JanPaneel indoor panel system. This panel has particularly good fire resisting- and sound insulating properties and is ideally suited for the quick installation of vacant properties and/or the renovation of existing buildings. The manufacture of this panel is bound by strict rules whereby repeatability of both quality and dimensional stability is a must.

For this, SenterTechnum has developed and built a new semi-automatic manufacturing facility. Materials are manually placed in pneumatic lockable adapters that form a stable package. This package is then horizontally in-line fully automatically screwed together from below and above. The whole line is adjustable so that different sizes of panel can be processed.

New modular construction process for mobile home floor building

New modular construction process for mobile home floor building

At Wanders Mobile Chaletbouw Ulft – NL mobile homes are designed and build to customer specification. Most of the construction work is manual, pure craftsmanship, and that is seen in the product! In this process, the floor construction work was the bottleneck. The floor was built on a steel chassis in almost one piece. All the required work, such as drilling holes, installing pipework and underneath cladding, adding insulation materials and mounting of floor cladding, took place on a serial basis.

SenterTechnum has introduced a completely new approach. Now, floor elements are built in standard modules reducing significantly manufacturing time of this part of the process. In collaboration with Poppers Senco, part of the required production system has been designed, manufactured and installed.

How do we work?

001

Partners

002

Planning

003

Design methodologies

004

Construction and installation

Stephan Koopmans – Founder

About Us

SenterTechnum contributes to improving production processes in the wood processing industry. Wood is a natural, sustainable and living material and combining wood with technology is a major challenge …

Product development, visual- and industrial design

Creativity, where practice, manufacturability and execution come together, forms the basis for a solution-oriented approach. Cost-driven innovation is desirable but not the sole consideration in the development of new products for industrial use. The strength of the applied technology is expressed in the support and control of the manufacturing process. This is the driving force behind SenterTechnum.

Project development and support

Innovating and investing can be complex and risky. Creating clarity and maintaining an overview with a market-driven focus, is a “must” to reduce risks and to support your business model. SenterTechnum has succesfully coordinated and managed decentralized project structures. The responsibility for implementation is placed where it belongs, at the root of project participants. At the same planning and methodology of execution is integrally and centrally coordinated with all parties involved. The aim is to unburden the customer… one central point of communication and knowledge.

Production processes for the wood processing and construction supply industry

Over the years SenterTechnum has become successfully involved in the innovation of manufacturing processes for the wood processing industry. This branch of industry is both market sensitive and conservative. When new automation technology presents itself, this industry is reluctant to invest. However, when craftsmanship is becoming increasingly scarce and expensive, the investment ratio shifts in favor of automation. A trend which is taking on ever greater proportions. The choice for SenterTechnum as a reliable partner for the design and implementation of this process is supported by knowledge, experience and the ability to bring the right parties together.

Automation, engineering and installation

Being successful in the implementation of automation is only possible when creative problem solving is combined with practical and economic usefulness. Automation requires specific knowledge and experience of all aspects of the development process and the implementation thereof. The design and construction of purpose build machines and equipment form the building blocks for successful automation. Installation and acceptance testing play also a key role.